Vision

Driven by scientific curiosity and the desire to develop high-quality, sustainable cosmetic products, we work as a team in a collaborative process that always results in an innovative product.

Our claim “Made in Germany” in combination with our openness to innovation ensures a dynamic that is reflected in the quality and diversity of our developments.

Dr. Thomas Kiepe, Geschäftsführender Gesellschafter

Facts

The KHK GmbH

KHK GmbH was founded over 30 years ago and is a medium-sized family business.

We research, develop and manufacture products for customers from the entire cosmetics segment specializing in the field of “water-free cosmetics”.

Company figures:

- Founded in 1992

- 45 employees

- 2-3 apprentices / dual students per year

- 4 boilers for different batch sizes from 25-900 kg

- 4 filling lines for hot filling in push-out tubes, top and back filling

- Printing machines for screen and digital printing

- Fully equipped laboratory for recipe development and various analyses

- Production in two shifts

- Capacity: Up to 23.5 million pieces/year

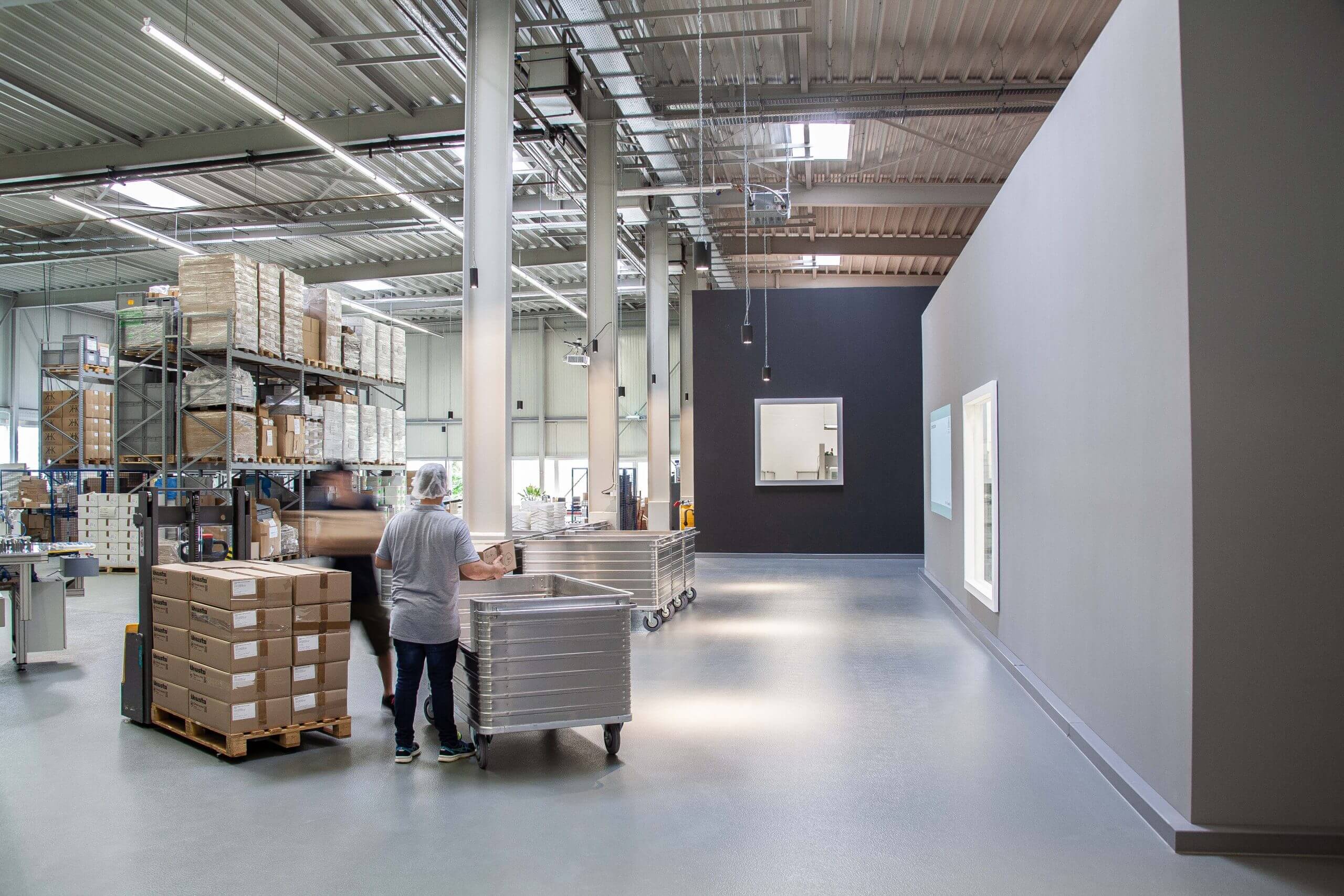

- Production and storage area: 2,030 sqm

- Office space: 400 sqm

- Export to 35 countries

Facts

The KHK GmbH

KHK GmbH was founded 30 years ago and is a medium-sized family business.

We research, develop and manufacture products for customers from the entire cosmetics segment specializing in the field of “solid lipids”.

Company figures:

- Founded in 1992

- 45 employees

- 2-3 apprentices / dual students per year

- 4 boilers for different batch sizes from 25-900 kg

- 4 filling lines for hot filling in push-out tubes, top and back filling

- Printing machines for screen and digital printing

- Fully equipped laboratory for recipe development and various analyses

- Production in two shifts

- Capacity: 23.5 million pieces/year

- Production and storage area: 2,030 sqm

- Office space: 400 sqm

- Export to 35 countries

Research

The future from our laboratory

Research

The future from our laboratory

To continuously expand our know-how, we have carried out various research projects in recent years. Our chemists are constantly researching innovative materials and formulations.

- Research project with the Technical University of Munich. The project was funded by the Germany’s Central Innovation Program for SMEs (ZIM) of the Ministry of Economics

- Research project “Development of processes for the homogenization of salts in fat masses and equipment for their processing” with support from the ZIM funding program

- Planning of a new research project in the coming year

- Resaerch budget currently amounts to 4.4 % of sales

Development

From the first idea to the manufactured product

After receiving your briefing, we start developing your customized formulation in line with your specifications:

- New development or adaptation of existing formulas according to customer briefing

- Research for raw material in the desired quality, e.g. from controlled organic or Fairtrade cultivation or with a focus on regional raw materials

- Testing and incorporation of provided raw materials

- Research and incorporation of special active ingredients

- Filling tests to ensure scalability

- Stability tests in the selected packaging material

- Support and implementation of certifications (e.g. vegan, halal, kosher, Fairtrade, NATRUE, COSMOS)

- Customer audits / audits by external certifiers

Production

State-of-the-art machines guarantee a smooth production process

By continuously investing in our state-of-the-art equipment, we are increasing productivity and reducing rejects, as well as improving scalability and optimizing the use of raw materials and energy.

- Analytical equipment: Melting point meter, density meter, refractometer and infrared spectrometer for monitoring raw materials and the produced bulk

- Climate cabinet and temperature cabinets for stability studies

- 4 boilers for different batch sizes from 25-900 kg

- 4 filling lines for hot filling in push-out tubes, top and back filling

- Capacity: 23.5 million pieces/year

- Finishing using a screen printing and digital printing machine

- Own injection molding tools for primary packaging

- Excellent quality management / quality control

- Production in line with Good Manufacturing Practices (GMP) ISO 22716 and ISO 9001:2015 for cosmetics

Cooperation partner

Strong partners for our success